The Ultimate Guide to Choosing the Best Driving School

March 1, 2025

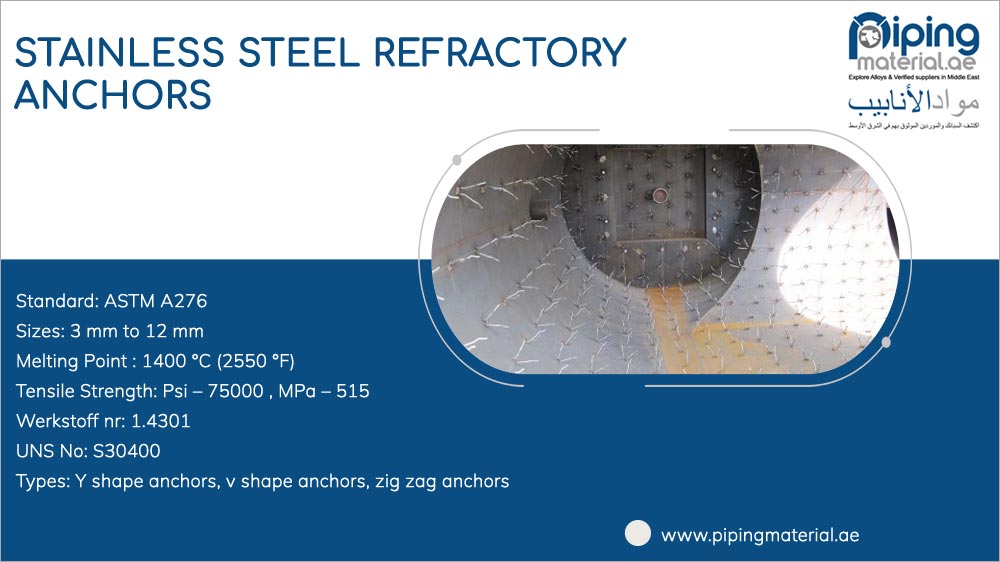

Why Stainless Steel?Stainless steel emerges as the material of choice for refractory anchors due to its exceptional properties that align perfectly with the demanding conditions of high-temperature environments.

Why Stainless Steel?Stainless steel emerges as the material of choice for refractory anchors due to its exceptional properties that align perfectly with the demanding conditions of high-temperature environments.Corrosion Resistance: Stainless steel is renowned for its resistance to corrosion, making it ideal for applications where exposure to aggressive chemicals or high temperatures is common. This characteristic ensures the longevity of refractory anchors, even in the harshest industrial settings.High Temperature Strength: The ability of stainless steel to maintain its structural integrity at elevated temperatures is a key factor in its selection for refractory anchors. This strength ensures that the anchors can withstand the extreme conditions within furnaces and other heat-processing units.Low Maintenance: Stainless steel refractory anchors require minimal maintenance, thanks to their corrosion resistance and durability. This not only reduces downtime for industrial processes but also contributes to cost savings in the long run.

Types of Stainless Steel Refractory Anchors:

Types of Stainless Steel Refractory Anchors:V-Anchors: Shaped like the letter "V," these anchors are versatile and suitable for various refractory lining configurations. Their design provides stability and resistance against movement.Y-Anchors: With a Y-shaped configuration, these anchors offer enhanced strength and stability. They are often used in applications where additional support is required to prevent lining failure.Crook Anchors: Recognized by their distinctive hook-like shape, crook anchors are effective in preventing the dislodgment of refractory linings under thermal stress.

Correct Spacing: Anchors should be spaced appropriately to distribute the load evenly across the refractory lining. This prevents localized stress concentrations that could lead to premature failure.Anchor Welding: Welding the anchors to the vessel's shell requires precision to avoid damaging the refractory lining. Skilled welding ensures a secure attachment without compromising the integrity of the anchor.Material Compatibility: The selection of stainless steel grade should consider the specific conditions of the industrial process. Factors such as temperature, chemical exposure, and mechanical stress play a role in determining the most suitable stainless steel alloy.

TAGS :

March 1, 2025

January 13, 2025